When it comes to the smooth and efficient operation of farm machinery, one vital component often overlooked is the Power Take-Off (PTO) drive shaft. This mechanical marvel plays a critical role in transferring power from a tractor to a range of attached equipment, including mowers, balers, tillers, and augers. Without a properly functioning PTO driveshaft, the productivity and efficiency of a farm can come to a halt.

Let’s delve into the importance of agricultural PTO drive shafts, with a special emphasis on the 540 PTO shaft, its design, benefits, safety features, and maintenance tips.

What Is a PTO Drive Shaft?

A PTO (Power Take-Off) drive shaft is a mechanical device used to transmit power from a tractor’s engine to an implement or attachment. It essentially bridges the gap between the power source (tractor) and the application (like a rotary tiller or mower), enabling the transfer of rotational energy needed for various tasks.

PTO drive shafts are designed to accommodate varying lengths and angular movements, which are common during farm operations. Built for heavy-duty performance, these shafts must withstand rigorous conditions such as rough terrain, high torque, and frequent motion.

Understanding the 540 PTO Shaft

One of the most common standards in agricultural equipment is the 540 PTO shaft. This term refers to the rotational speed of the shaft—540 revolutions per minute (RPM). It is the standard PTO speed for many tractors and implements, particularly in North America.

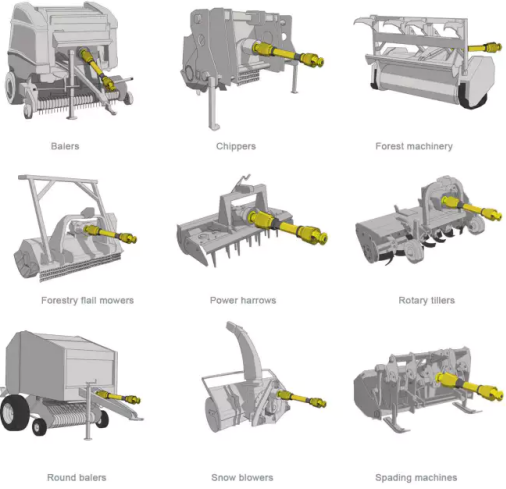

The 540 PTO shaft typically features a 6-spline connection, making it compatible with a wide variety of farming equipment. This shaft speed is ideal for attachments that don’t require high-speed operation but need consistent torque delivery. It is especially common in implements such as:

- Rotary cutters

- Post hole diggers

- Fertiliser spreaders

- Manure spreaders

Using the correct PTO speed is critical. Operating a 540 RPM implement on a 1000 RPM PTO shaft, for example, can damage equipment and create safety hazards. That’s why matching the PTO drive shaft specifications—particularly the speed—is essential for proper function.

Key Features of a High-Quality PTO Drive Shaft

To perform efficiently and safely, a PTO drive shaft must include specific design and material characteristics:

1. Durability

PTO shafts are built with hardened steel and precision engineering to handle the demanding conditions of agricultural work. A high-quality 540 PTO shaft will resist wear and provide reliable performance over time.

2. Telescoping Tubes

These tubes allow the shaft to adjust in length, accommodating different distances between the tractor and the implement. This flexibility prevents stress and strain on equipment during turns and uneven terrain.

3. Universal Joints (U-Joints)

U-joints help the shaft operate at various angles without losing rotational power. They ensure a smooth transfer of energy even during tight turns or equipment movement.

4. Safety Shields

Modern PTO shafts come with safety guards or shields to protect the operator from spinning parts. These are crucial for preventing accidents and must never be removed or damaged.

5. Quick-Release Yokes

These allow for rapid attachment and detachment of the shaft, improving efficiency during equipment changes.

Safety Considerations

PTO shafts can be dangerous if not used properly. According to farm safety statistics, injuries related to PTO entanglements can be severe and even fatal. Here are a few safety tips:

- Never wear loose clothing near PTO equipment.

- Always turn off the tractor and disconnect the PTO before servicing or adjusting implements.

- Inspect safety shields regularly and replace them if damaged.

- Keep bystanders, especially children, away from operating machinery.

Safety is paramount. Investing in a 540 PTO shaft with reliable shielding and secure locking mechanisms reduces the risk of accidents significantly.

Maintenance Tips for Longevity

Proper maintenance of your PTO drive shaft ensures optimal performance and extends its lifespan. Here are a few maintenance tips:

1. Regular Lubrication

Grease the universal joints and telescoping sections regularly. Dry joints can lead to excessive wear and eventual failure.

2. Check for Wear

Inspect the splines, U-joints, and safety shields for any signs of damage or excessive wear. Replace parts promptly to prevent breakdowns.

3. Alignment

Ensure the PTO shaft is properly aligned with the implement. Misalignment can cause vibration, damage, and reduced efficiency.

4. Storage

When not in use, store the shaft in a dry place, preferably off the ground, to prevent rust and corrosion.

Choosing the Right 540 PTO Shaft

When selecting a PTO drive shaft for your equipment, it’s crucial to consider:

- Length and size required for your implement

- Horsepower capacity

- Connection type (typically 6-spline for 540 RPM models)

- Safety features such as guards and locking systems

Buying from reputable manufacturers or dealers ensures you’re getting a product that meets agricultural safety and quality standards.

Conclusion

The agricultural PTO drive shaft, especially the 540 PTO shaft, is a cornerstone of modern farming equipment. It provides the vital link that powers essential machinery, driving efficiency and productivity on the farm. By choosing the right shaft, following proper safety measures, and maintaining it regularly, farmers can ensure smoother operations and avoid costly downtime.

Whether you’re baling hay, mowing fields, or fertilising crops, the performance and reliability of your 540 PTO shaft can make a world of difference in your daily farming tasks. So, don’t underestimate this powerful connection—treat it as the essential component it truly is.

Do you have any questions about HZPT‘s products or services? Reach out to their expert team to find the right agricultural PTO shaft solution tailored to your machinery and performance needs.