In the intricate landscape of manufacturing, downtime emerges not just as an inconvenience, but as a formidable financial adversary. Every moment a production line grinds to an unexpected halt represents not just lost productivity hours, but a significant drain on resources and, perhaps more importantly, erodes the foundation of trust—a cornerstone of any manufacturer’s relationship with its clientele.

The true cost of downtime extends far beyond mere operational disruptions. It strikes at the heart of customer relationships, undermining the trust painstakingly built over time. Failing to meet commitments due to operational interruptions strains these vital relationships, leaving customers disenchanted and potentially seeking alternative partnerships. In the competitive marketplace, where speed and reliability are paramount, any deviation from expected delivery schedules can be detrimental.

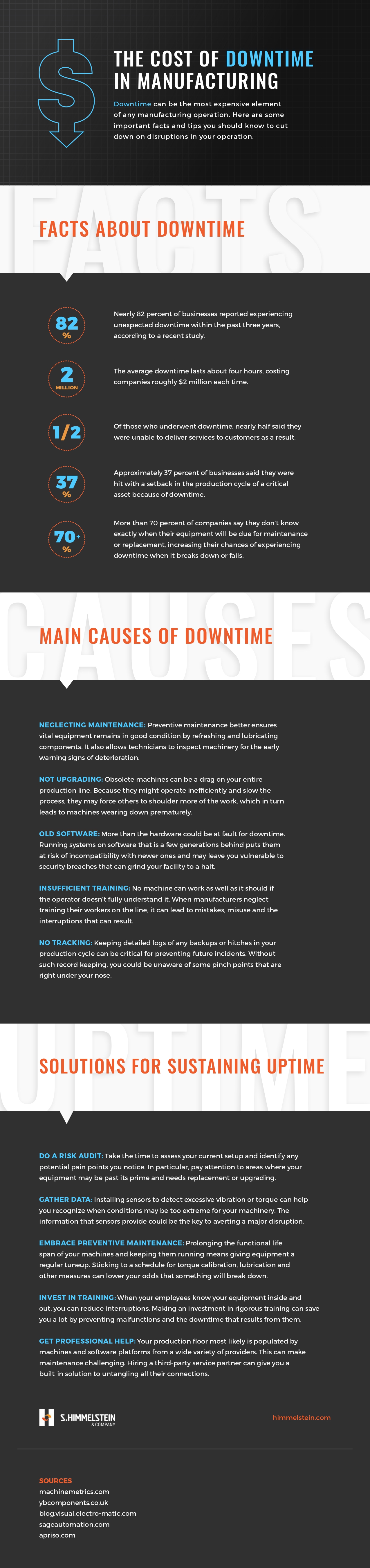

While some disruptions are inevitable, a substantial portion of downtime incidents are preventable. Within manufacturing environments, these disruptions often trace back to neglect—whether it’s the oversight of preventive maintenance schedules, deficiencies in employee training, or lapses in effective data management. These seemingly minor oversights have a cumulative effect, morphing into catastrophic setbacks capable of bringing entire operations to a standstill.

Fortunately, proactive measures and upfront investments offer a shield against such setbacks, ensuring a seamless production cycle and bolstering customer confidence. By prioritizing preventive maintenance, investing in comprehensive employee training programs, and implementing robust data management systems, manufacturers can significantly mitigate the risk of downtime and its attendant consequences.

For actionable insights into averting downtime within your facility, continue reading on through the resource highlighted alongside this post. It serves as a valuable resource, offering practical steps to safeguard against disruptions and highlighting their critical importance in maintaining uninterrupted manufacturing workflows.

The Cost Of Downtime In Manufacturing, provided by S Himmelstein and Company, the organization to shop with for your next torque transducer